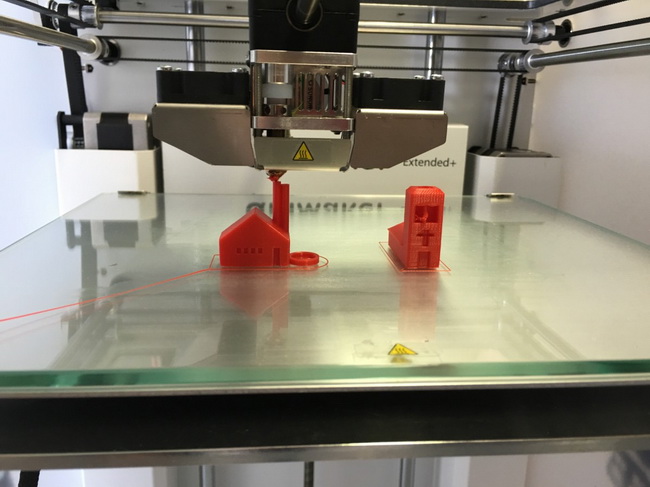

3D printing is based on a production process called additive manufacturing. Engineers or designers, create a 3D model of whatever they want to have as a final product, using CAD (Computer-Aided Design) programs, and give a ‘command’ to the 3D printer, which then has to build this model up layer by layer, until the whole shape is complete.

Right now, in the 21st Century, affordable housing remains a big problem around the world. Inadequate distribution of housing units and shaky economical conditions contribute to evictions, and the inability of people to meet the financial requirements of decent accommodation. It happens everywhere. Brazil has almost 20% of its population living in brutal conditions, without stable homes. Even in the US, there are areas still affected by insufficient housing.

So what can be done about it? There can be long, elaborate, and usually futile debates on how we can help the economy of a whole country, or we can consider this as an engineering problem. Admit it, these guys are wired to find solutions! So can 3D printing be a solution? Let’s dig a bit to see if that’s the case.

3D printing

If you’ve never wondered what 3D printing actually is, let’s go into more detail and determine what this process entails. 3D printing is based on a production process called additive manufacturing. Engineers or designers, create a 3D model of whatever they want to have as a final product, using CAD (Computer-Aided Design) programs, and give a ‘command’ to the 3D printer, which then has to build this model up layer by layer, until the whole shape is complete.

Any 3D printer, from a table-top cheap 3D printer, to a huge construction model, is based on the same general principle. A 3D printer has a support system, or a frame, that has to firmly stay in place, while the other part, the nozzle, moves around and distributes the material in thin layers.

How elaborate can the 3D model be? Well, let’s say it’s limited by the size of the device itself and by the imagination of the person coming up with the design. How intricate can the print be? That depends on the printer, and how advanced it is. Some printers are capable of impressive detailing, others are not that proficient.

Construction 3D printing

As we arrive at the main topic, there are so many questions that 3D printing has to answer before it can actually propose a solution to the housing crisis.

Construction 3D printers use the same general principle of additive manufacturing, and most models use a concrete-like substance as their main material. Unlike the ‘table-top’ 3D printers, these machines have a much tougher problem to tackle. Adequate distribution of dense material, Insulation, heat transfer, durability, weather conditions. These are examples of the sort of problems that construction 3D printing has to solve. Plus, construction 3D printing still requires a high level of human involvement, as the foundation, the plumbing, the wiring, the roofing, etc., are still performed by manual labor.

Nowadays, there are a few models of construction 3D printers, being developed all over the world ( in Denmark, the US, Italy, Sweden, etc.) that offer affordable housing for people who are forced to live in inhuman conditions. Like the Icon Vulcan II, a startup developed in Austin, that recently collaborated with a number of non-profits to build a community of 50 homes, in a part of Latin America, that is in dire need of stable housing. The Vulcan uses a custom mix of concrete to make the houses durable, and the configuration of the printer allows for great design possibilities.

There are other notable companies in the field, like Apis Cor, that developed a printer which, unlike the Vulcan, doesn’t have a frame, but rather relies on a very stable base and rotates 360, much like a crane. This printer had massive success in Dubai, where it built the 2-storied Municipality building. Apis Cor 3D printer is very fast and can put up walls for a standard home in a few days’ time.

Cobod is one of the most notable 3D printing companies in the European arena. Developed in Denmark, it created the first 3D printed building in Europe. This 3D printer also uses a large-scale frame to support the nozzle, rather than having a crane-like construction. This frame ensures high precision and the Bod II can go as high as 3-stories, constructing buildings for various purposes.

Advantages of 3D printing vs. traditional construction

So let’s list all the evident advantages 3D printing has over the traditional means of construction:

- Time-efficiency. Let’s say you want to build a 1000 sq ft house. How long will that take, given that all the work on design has already been done. A couple of weeks? A month? A construction 3D printer can tackle that job in a few days. Let’s note that we are talking about the walls only, as the foundation and the roofing, and all the other processes require the same amount of time in both cases, but printing certainly does speed things along.

- Savings. Printing a house is much cheaper, than buying one that’s already standing, or even building one from scratch. Plus, it’s a more material-efficient method of building, which can save money as well. Especially in the US, but not exclusively. 3D printing has a real chance to make housing more affordable in countries already on the verge of a catastrophe.

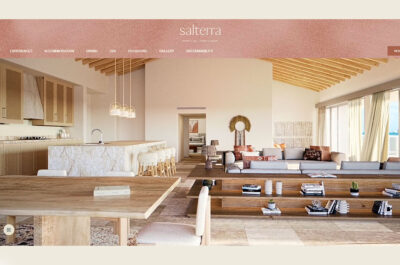

- Original design. Because of their configuration, many printers use round forms to create their houses and as a result, get very original and futuristic architecture. Naturally, there are problems associated with that as well, which engineers have learned to avoid, but still, the rounded corners and the round walls are such a fresh and stable solution!

Is it worth it?

We think that relying on humans while building houses is just fine. It creates endless jobs for thousands of people. But if you ask, is 3D printing worth the trouble, the answer would be: absolutely. Today we are facing a new world, where software and material science have merged in one, and it gives us a deep pool of opportunities. We say, why not use them, and open up new opportunities for people who can’t afford traditional housing!

Naturally, this technology is just starting its development, but we are certain that the success will be tremendous and many breakthroughs are yet to come!